Denzil S Davies

Precision CNC Machinist • Lean Specialist • Tool Innovator & Product Designer

Precision CNC Machinist • Lean Specialist • Tool Innovator & Product Designer

I'm a creative CNC machinist with a relentless drive to make things better, whether it's streamlining a shop process or designing tools that solve real-world problems. I thrive on turning ideas into reality, blending hands-on precision with innovative thinking to optimize workflows and create efficient solutions.

That passion for improvement shows up in everything I do. For instance, I love tinkering with systems to boost efficiency, like getting a tool life management setup running smoothly for a complex production cell with multiple horizontal machines, or implementing a QR code system that cut down time on part sign-outs in our ERP. In past projects, I've scripted ways to analyze CNC programs for optimal tool setups and even updated post processors to dynamically tweak feeds and speeds for varying machine capabilities, always with an eye on lean principles and continuous kaizen.

Outside the shop, I'm fueled by creativity and adventure. Skiing is my ultimate escape, I've competed at a low level on UK indoor slopes and even won the British Indoor Ski Cross championships in 2009. It's that love for the mountains that inspired side projects like my Pro Snow Tools, and it keeps me pushing boundaries in design and making. Whether it's 3D printing intricate lampshades or laser-cutting custom pieces in my spare time, I enjoy exploring new ways to build and innovate.

I'm excited about opportunities in CNC machining, product design, software tools for manufacturing, or consultancy roles where I can bring fresh ideas to help teams thrive.

Precision-machined rear upper control arms from billet 6061 aluminum. Programmed, setup, and produced in two operations using a 4th-axis CNC setup at Focus Manufacturing, showcasing efficient production workflows and advanced machining capabilities.

Precision ski & snowboard edge maintenance tools. Includes a sidewall removal tool and a Dremel-compatible sharpening attachment with interchangeable angle plates (90° to 85° bevel) for perfect edges every time.

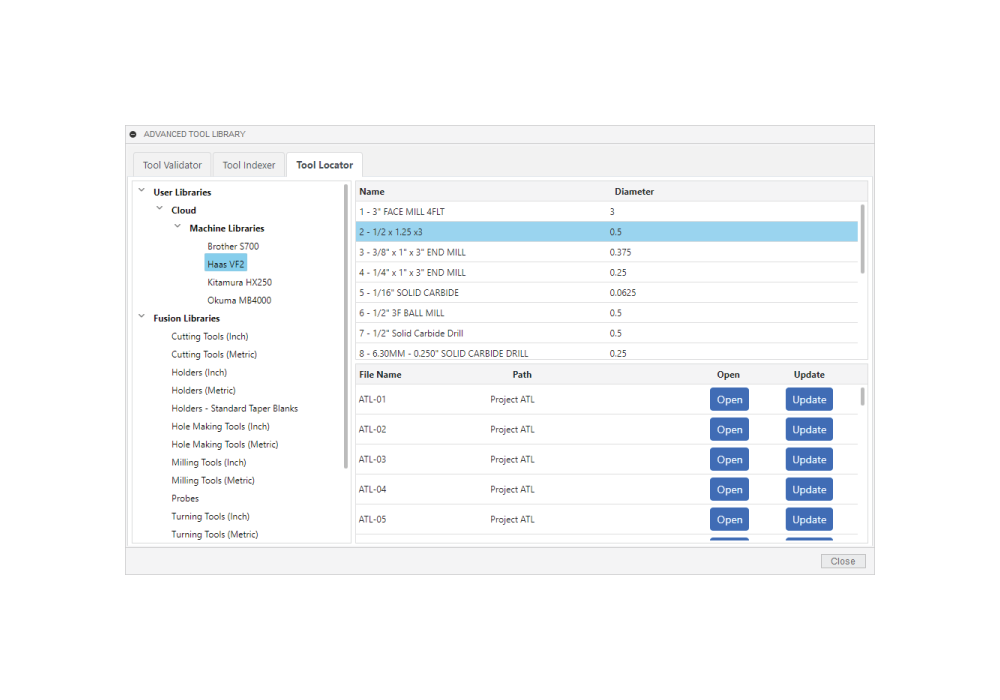

A powerful Fusion 360 add-in for CNC machinists and CAM programmers. Features tool validation, usage indexing, and smart library management to streamline tool selection and reduce errors.

A modern geometric pendant lampshade with an intricate honeycomb pattern that filters light to cast captivating shadows, enhancing any space's ambiance. Designed in 2D for efficient 3D printing in metallic PLA, the pieces form elegant Gaussian curves and assemble using custom 3D printed rivets. This project required extensive mathematical calculations to achieve the desired shape, demonstrating precision design and additive manufacturing innovation.

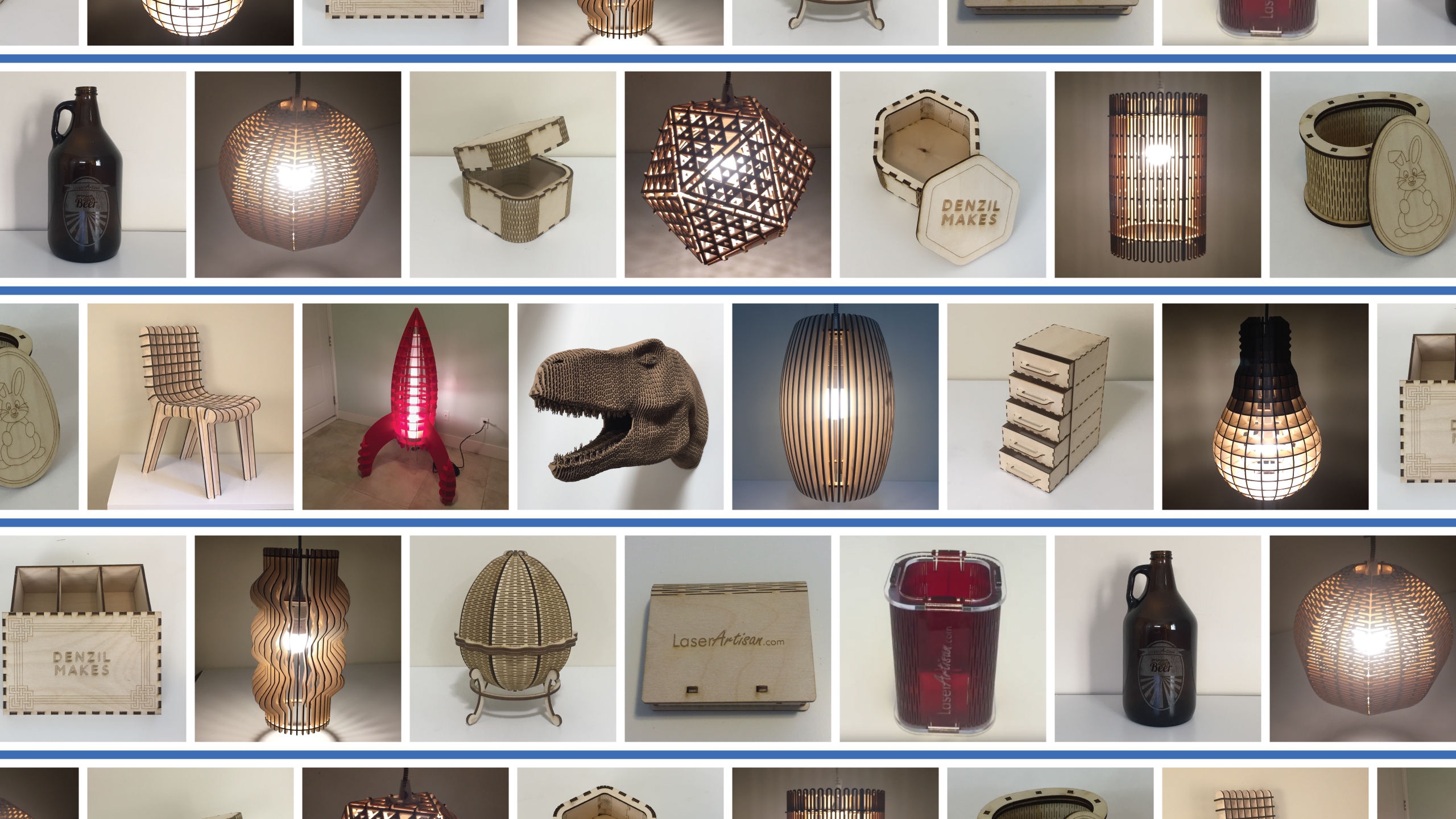

A collection of creative laser-cut projects, from layered art and lampshades to functional items like wine racks and living hinge designs. Rooted in my early experience programming Bystronic laser cutters for steel, stainless steel, and aluminum at my first manufacturing job, these spare-time creations hone my Autodesk Fusion 360 modeling and design skills. Explore more on my YouTube channel.

Prior to moving to Canada in 2016, I founded and operated a successful UK-based business specializing in custom house numbers. Utilizing a range of tools including laser cutters, CNC routers, and vinyl cutters, I personally designed and produced all items from diverse materials such as acrylic, slate, ACM (aluminum composite material), and wood. Sales were driven primarily through eBay with additional listings on Etsy, enabling worldwide shipping and a global customer base. This venture honed my entrepreneurial skills alongside precision manufacturing expertise.